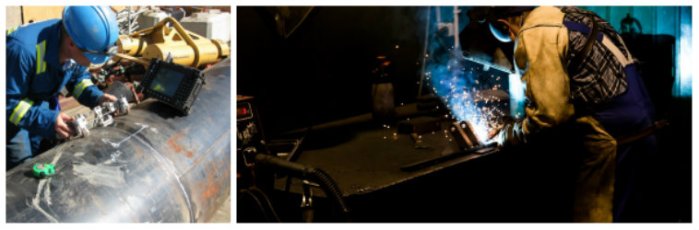

Welding is a sculptural process of binding and joining metals or thermoplastics by causing fusion. Welding melts the base metal and a filler material is typically added to the joints to form a pool of molten material. This molten metal then cools down to form a joint.

There are different methods for welding and each has its own pros and cons. For example, there are less common methods for welding processes such as friction welding in which the base metal does not melt.

Some mostly used welding methods as revealed by the experts in non-destructive testing are:

-

Oxy-fuel welding – This method is also known as oxyacetylene welding or oxy-welding in short. It uses fuel gas and oxygen to weld and cut metals.

-

Shielded metal arc welding – Better known as ‘stick’ or ‘electric’ welding, this method uses a flux coated electrode. The electrode holder holds the electrode as it slowly melts away.

-

Gas tungsten arc welding – Also known as TIG, this one uses a non-consumable tungsten electrode to produce the weld. The welded area is protected from atmospheric contamination by an inert shielding gas such as argon or helium.

-

Gas metal arc welding – Mostly termed as MIG, it uses a wire feeding gun that feeds wire at an adjustable speed and flows an argon-based shielding gas or a mix of argon and carbon dioxide over the weld puddle to protect it from atmospheric contamination.

-

Flux-cored arc welding – Almost same as MIG except the fact that it uses a special tubular wire filled with flux. It can be used with or without shielding gas, depending on the filler.

-

Submerged arc welding – This method uses an automatically fed consumable electrode and a blanket of granular fusible flux. The molten weld and the arc zone are protected from atmospheric contamination by being “submerged” under the flux blanket.

-

Electroslag welding – This one is a highly productive method using single pass welding process for thicker materials between 1 inch and 12 inches in a close to vertical position.

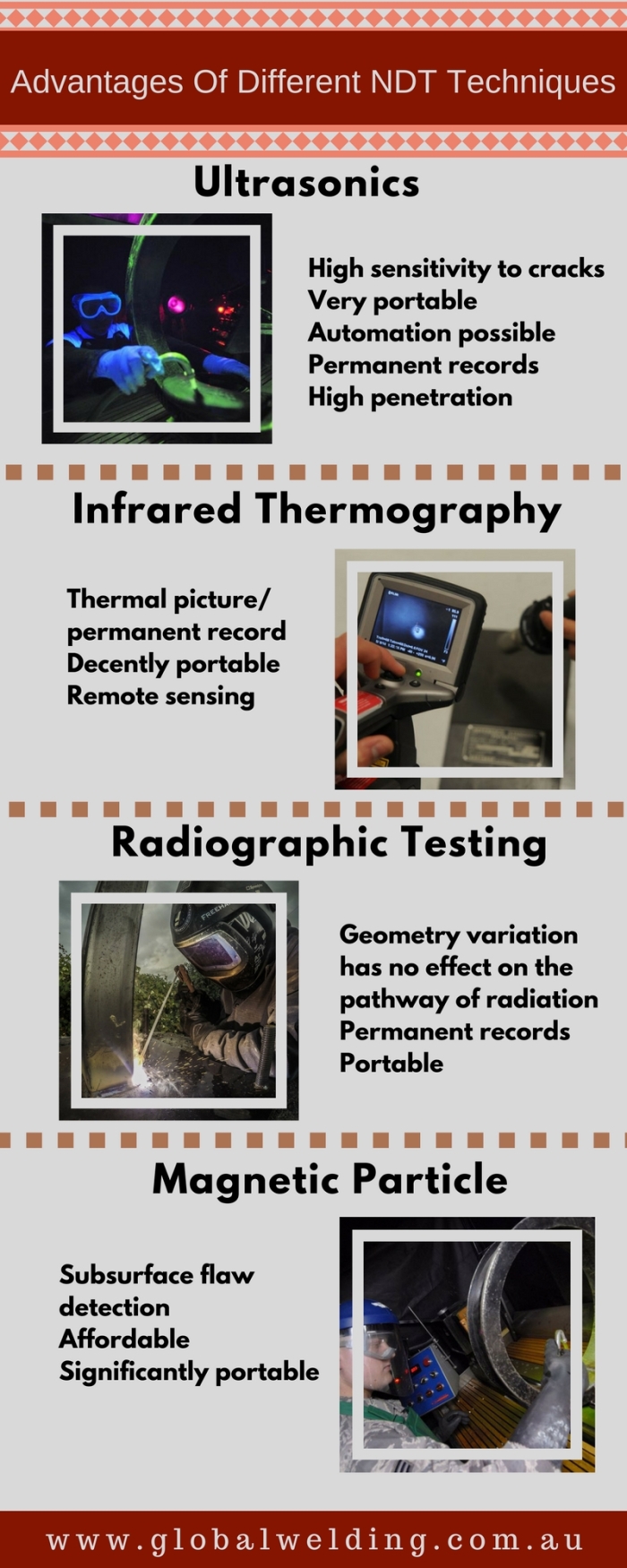

There are a number of companies providing services for welding inspection, welding supervision and non-destructive testing (NDT). Inspection is readily necessary after the job is done and should not be left out, since it might prove to be dangerous afterwards.